Miltec is a family owned and operated milling business in Volksrust, Mpumalanga, South Africa, started by Kevin Kieser’s father in 1975. When market demands changed early in the new millennium, Kevin was at a crossroads: adapt or get out of business. Here’s how he faced the challenge head-on with the help of Roff Milling.

EARLY DAYS

In 1975, Kevin Kieser’s father bought an old maize mill in the Mpumalanga town of Volksrust. For close to five years, he ran this mill with an output of 500kg per day. It was not a profitable business, so he built his own mill in the 1980’s, which took the best part of about four years to complete and which produced a brilliant maize meal.

When Kevin joined the business in 1995, Miltec was doing very well and its special maize meal* was a big hit amongst customers.

ADAPT OR PERISH

But in the middle of the 2000’s Kevin noticed that trends started shifting as super maize meal** became the preferred product in the market.

Sales were dropping every month. Sadly, his father also passed away in 2005, and the future of the mill looked uncertain. Kevin knew he had to do something to turn things around, and was passionate about finding a solution. He did his research online, looking for a cost-effective maize milling system.

A SOLUTION FROM ROFF

Kevin was familiar with Roff Industries, and knew them for their smaller mills, but was pleasantly surprised when he discovered that they also manufactured industrial milling machines.

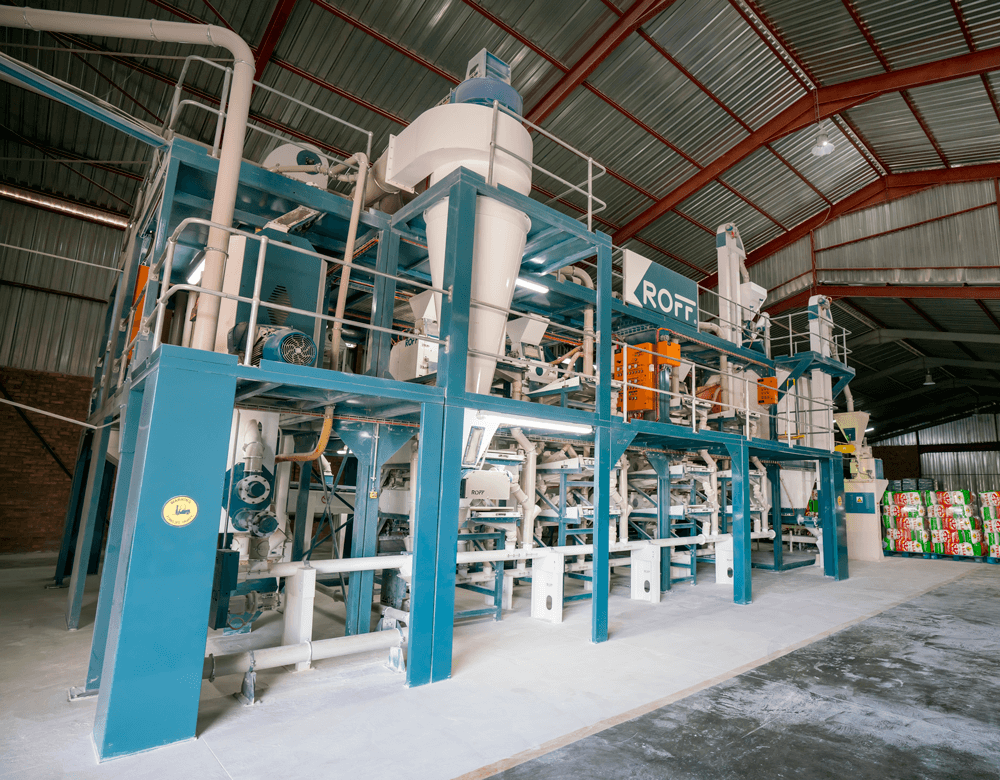

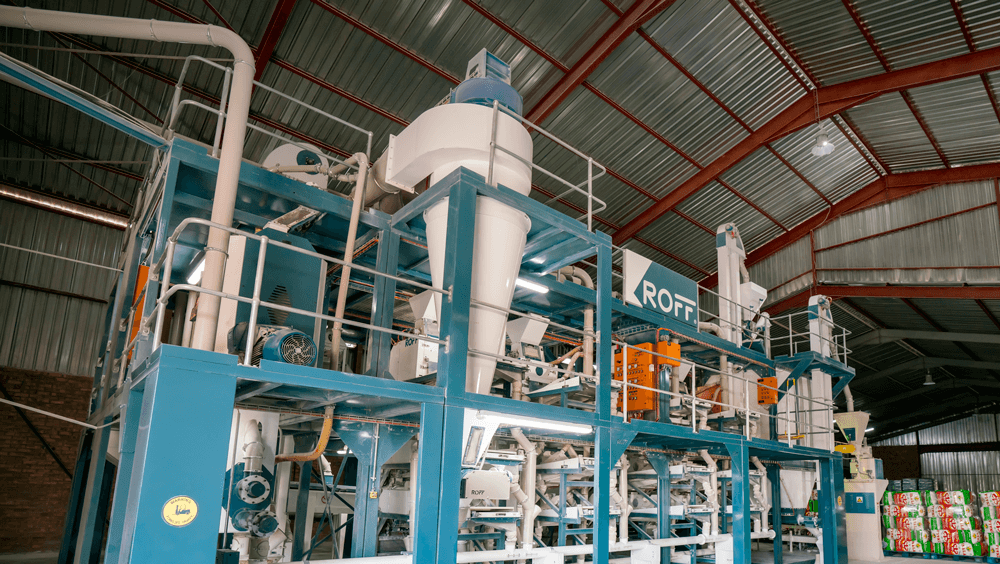

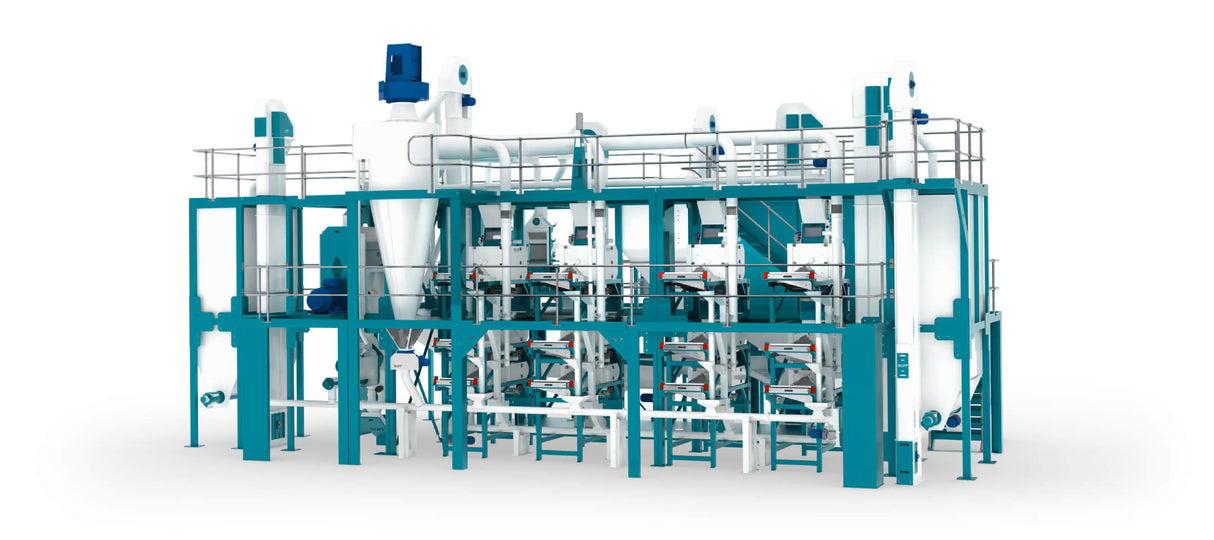

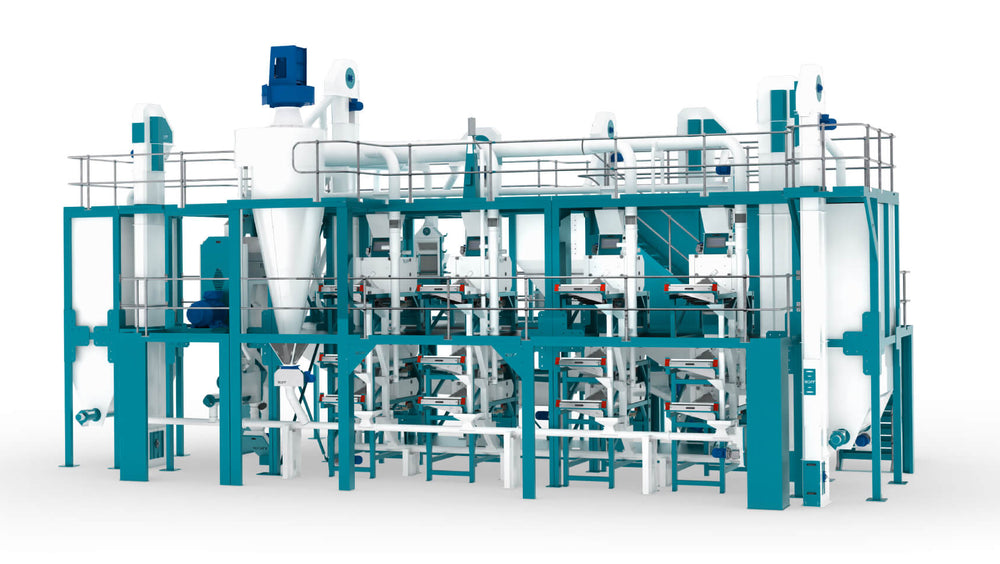

The technical team told him about the exciting flagship R-70 milling system, which had just been launched. With a footprint of just 120m2 and 7 metres in height, Kevin could imagine the possibilities. Says Kevin: “If it could produce a top-quality maize meal, I knew that this was the mill for me.”

Thanks to Roff’s efficient technical team, the mill was set up and running within days. The R-70 has a milling capacity of 2.5 tons per hour, which can be increased to up to 5 tons per hour to cater for growing demand. Once Kevin saw the quality of the maize meal that came off the mill, he realised that meeting a growing demand would soon be on the cards for Miltec.

Watch Kevin Kieser tell his story:

LOOKING FORWARD TO THE FUTURE

“It’s a great feeling to be competitive in the market and to have happy customers. Our business has grown exponentially, and we are now also distributing to surrounding towns and rural areas,” explains a proud Kevin. “Roff has given me a new lease on life within a milling context. I’d recommend them to every business person out there.”

If you would like to enjoy success in milling like Kevin Kieser from Miltec does, choose the right milling partner. Choose Roff Milling.

THE ROFF R-70 MAIZE MILL

The turnkey R-70 mill can be shipped and installed in about six to eight months from order. The R-70’s compact size fits most existing warehouses with only minor adjustments needed to the roof height. Operation and maintenance is simple and easy, and Roff’s technical team trains your team on-site to operate and maintain the mill while it’s being installed and commissioned.

*Good quality but less refined maize meal from a milling process without degermination

**Refined maize meal that has undergone degermination